In traditional power safety inspections, special personnel are responsible for the inspection and management of power equipment, including field and substation equipment inspection management. Many problems often occur, such as: the video cannot be returned, resulting in low communication efficiency; the inspection route cannot Planning and tracking lead to unknown progress; no video and picture retention, data omission; inspections in special environments such as high pressure or high altitude are also limited, inspection information cannot be returned in time, data sharing channels and query statistics methods are lacking, and traditional The paper-and-pencil entry method has caused data irregularity, error-proneness, and low efficiency. Onethingcam 4G helmet OTC-W10 is integrated with multiple functions and intelligently manages wearable inspections, which can effectively solve the inspection problems of traditional power and improve inspection efficiency and quality.

Video export collection cabinet for 4G smart helmet

OTC-W10 integrates high-definition video, audio, 4G and WiFi wireless communication, GPS positioning, storage, alarm and other modules in one, which can record site conditions in real time, collect evidence, and standardize construction. The front-end equipment collects and transmits on-site images and high-precision positioning information in real time to the back-end command center management platform. At the same time, the front-end equipment integrates advanced intelligent algorithms to realize intelligent face attendance, chart recognition, GPS electronic fence, dangerous working area setting and multiple safety Warnings, etc., to fully guarantee work safety supervision.

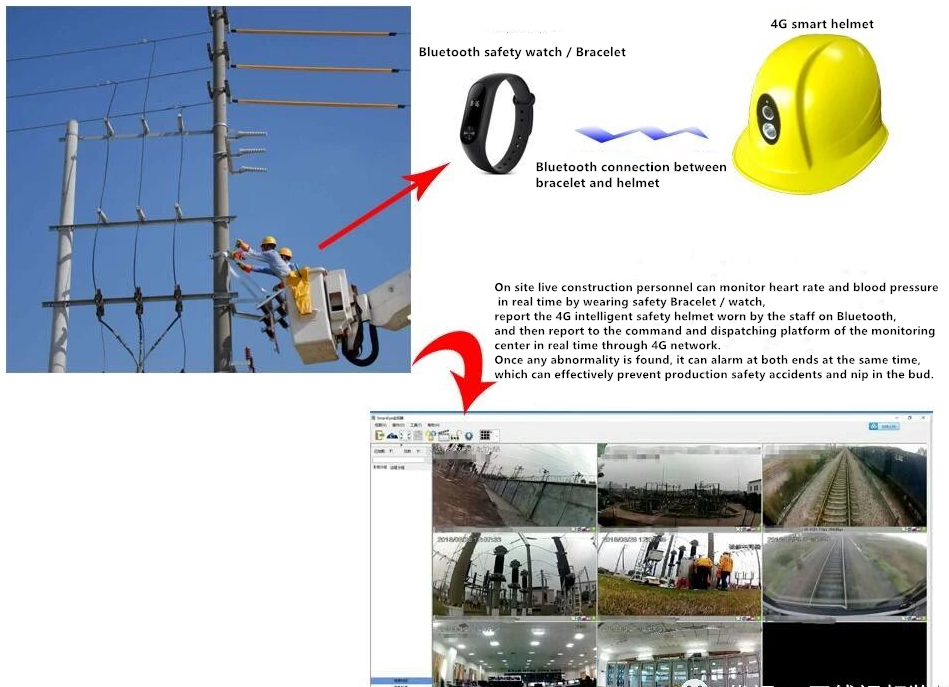

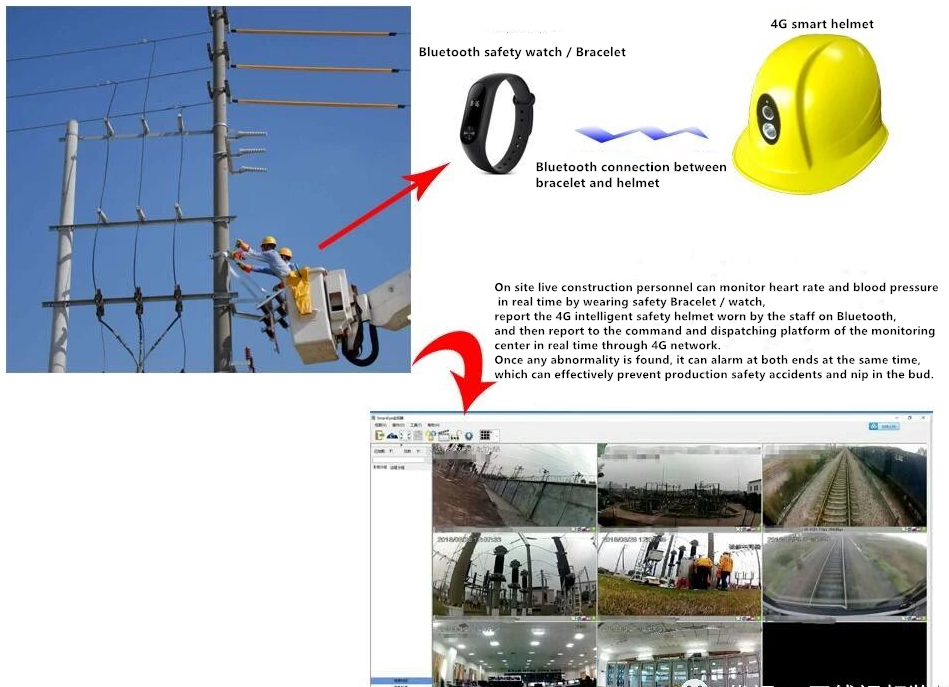

On-site live construction workers can monitor their heart rate and blood pressure in real time by wearing a safety bracelet/watch, and report to the 4G smart helmet worn by the staff via Bluetooth, and then use the 4G network to report to the command and dispatch platform of the monitoring center in real time. At the same time, both the front and the rear are alarmed, which can effectively prevent safety production accidents and prevent problems before they happen.

Intelligent video analysis assists safety production management

(1) Remotely conduct unified management of scattered construction sites, avoid frequent use of manpower to go to the site for supervision and inspection, reduce the cost of site personnel management, and improve work efficiency.

(2) Through the video monitoring system, we can timely understand the real-time construction situation, construction dynamics and progress of the construction site, and whether the preventive measures are in place, especially for the construction site with relatively large scenes, and the enterprise leaders of key projects also need remote supervision.

(3) Supervise the property safety of building materials and construction equipment on the construction site to avoid the loss or theft of items causing losses to the enterprise.

(4) Show the actual construction situation in front of the customer, show the construction plan and image progress of the site to the customer, and achieve a publicity effect.

(5) Prevent outsiders from over boarding, crossing borders, intruding, intruding into dangerous areas, warehouses and other places to ensure the property and personal safety of the construction site.

Products are widely used in various industries such as firefighting, emergency rescue, electric power inspection, railway maintenance, construction site operations, oil and oil wells, thermal maintenance and security patrols.